Relied On Tahoe Instrument Cluster Repair Specialists: Recovering Gauge Precision

Relied On Tahoe Instrument Cluster Repair Specialists: Recovering Gauge Precision

Blog Article

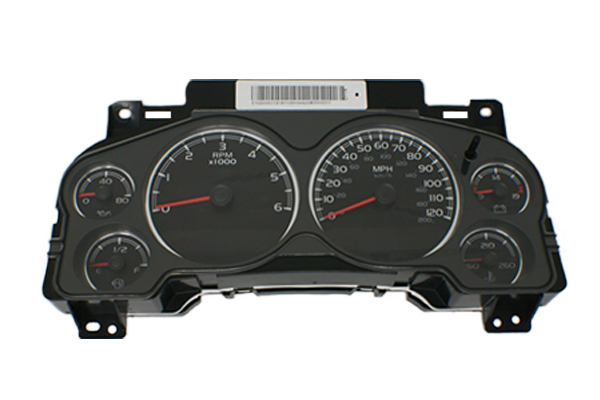

Comprehensive Solutions for Reliable Car Tool Cluster Repair Service and Reconstruction

In the detailed network of parts that make up a vehicle, the tool collection stands as a critical interface between the driver and the vehicle's crucial information. They can interfere with the smooth performance of the automobile and concession safety and security when issues arise within this essential system. As drivers increasingly depend on the details showed on these digital dashboards, guaranteeing the reliability and precision of the tool cluster becomes critical. In the world of car maintenance and repair service, finding extensive services for dealing with tool collection breakdowns and wear and tear is not only an issue of benefit yet a requirement for optimal lorry performance. By exploring innovative repair work strategies, precautionary maintenance ideas, and cutting-edge modern technologies, a course to achieving reputable instrument collection repair work and restoration arises. Nevertheless, the essential hinge on recognizing one of the most efficient methods and professional services that can assure a smooth resolution to these complicated issues.

Common Instrument Cluster Issues

When diagnosing car tool cluster problems, it is vital to identify the most typical breakdowns that can occur. One more usual trouble is backlighting failure, which results in dim or non-functional illumination behind the tool cluster, making it challenging to check out the display screens, particularly in reduced light problems. Wiring problems, blown integrates, or deterioration can also lead to instrument collection breakdowns.

Advanced Fixing Techniques

Carrying out cutting-edge diagnostic tools and specialized strategies enhances the accuracy and performance of car tool cluster fixing and repair procedures. Advanced repair strategies play a critical duty in resolving complex issues that may not be dealt with with conventional techniques. One such method is micro-soldering, which includes complex soldering of small elements on the circuit card to take care of connection problems. Utilizing this method requires experienced service technicians with a consistent hand and substantial experience in working with delicate electronic components. In addition, advanced programming devices are used to reprogram and rectify the tool cluster to make certain exact analyses and performance. These tools permit modification of settings based on the vehicle's requirements, supplying a tailored solution for each and every repair service. Furthermore, optical lens polishing techniques are made use of to eliminate scratches and boost exposure on the instrument collection screen. By incorporating these sophisticated repair strategies, service technicians can deliver dependable and long-lasting options for car instrument collection repair work and remediation.

Preventive Upkeep Tips

To make certain the longevity and ideal efficiency of fixed instrument clusters, adherence to precautionary upkeep pointers is critical in protecting the detailed repairs carried out with progressed techniques. One necessary preventative maintenance suggestion is to on a regular basis check for any type of indications of damage on the tool collection, such as faded displays or malfunctioning gauges. Dealing with these problems quickly can stop more damages and guarantee the cluster remains to work correctly.

In addition, keeping the lorry's electric system can likewise contribute to the longevity of the tool collection (tahoe instrument cluster repair). Examining the battery regularly, guaranteeing proper grounding, and addressing any kind of electric problems promptly can protect against damages to the cluster's fragile parts

Cutting-Edge Technologies

Incorporating state-of-the-art technological improvements into automobile instrument collection fixing and reconstruction processes boosts effectiveness and accuracy, raising the industry criteria for precision workmanship. One of the sophisticated innovations revolutionizing this area is the utilization of innovative diagnostic devices and software. These devices enable service technicians to identify detailed issues within the tool cluster quickly and properly, resulting in expedited fixing times and enhanced total functionality.

Additionally, the execution of software updates and recalibrations through specialized programs user interfaces has actually become an important facet of modern-day instrument cluster repair work. This innovation permits for the modification of setups tailored to particular automobile designs, making certain optimum efficiency post-repair.

Additionally, the integration of augmented truth (AR) and online truth (VIRTUAL REALITY) applications is changing the means professionals interact with instrument clusters during the remediation process. AR and VR technologies provide enhanced visualization capabilities, providing comprehensive insights into the collection's inner parts and promoting specific fixing and reconstruction treatments.

Expert Repair Solutions

With the evolution of cutting-edge technologies in vehicle tool cluster repair work and remediation shaping industry practices, the need for specialist repair services has heightened dramatically. Specialist repair services play an essential role in hop over to here ensuring that vehicle instrument clusters are fixed and brought back to their optimal capability and aesthetic appeal. These solutions are supplied by proficient specialists who have know-how in identifying issues, fixing electronic parts, and bring back the appearance of tool clusters to factory requirements.

Professional repair services include a series of specialized procedures, including motherboard repair work, odometer corrections, pixel screen fixes, and lens replacements. Technicians use innovative equipment and industry-specific understanding to address a range of concerns, such as dead pixels, gauge malfunctions, backlight failings, and much more. By handing over instrument cluster repair to specialists, car proprietors can take advantage of accurate repair services, dependable efficiency, and expanded longevity of their clusters.

Final Thought

By exploring advanced fixing strategies, preventative upkeep pointers, and sophisticated modern technologies, a course to page accomplishing trustworthy instrument cluster repair and restoration arises. By incorporating these sophisticated repair work techniques, technicians can deliver reliable and durable services for car tool collection repair work and restoration.

To ensure the long life and ideal performance of fixed tool clusters, adherence to preventative maintenance tips is extremely important in protecting the elaborate repairs performed with progressed methods. By turning over tool collection remediation to professionals, lorry owners can profit from precise repairs, trusted efficiency, and extended durability of their clusters.

In verdict, dealing with usual instrument collection problems via advanced repair service techniques, preventive upkeep pointers, and innovative innovations is important for making certain trusted auto tool cluster repair work and remediation.

Report this page